AHEAD 2015-2019

Description of the infrastructure

The Centre Spatial de Liège (CSL) is part of the University of Liège and is specialised in the evaluation of optical payloads in simulated environment since the early 70’s. Telescopes and space science instruments that have been tested at CSL cover the full electromagnetic spectrum, from X-rays to far infrared. Through every specific case, CSL team has gained unique experience and enlarged its testing capabilities to meet a wide range of test conditions and payload dimensions.

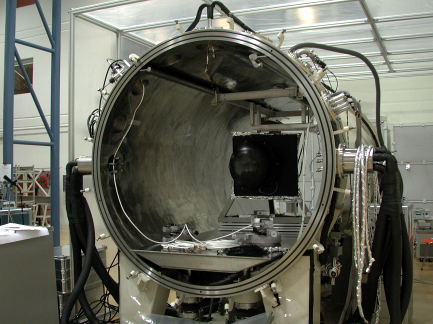

Installation 1: FOCAL2 – One thermal vacuum chamber is proposed in this project: FOCAL 2 (2m diameter). The chamber is located in a clean rooms whose cleanliness is permanently controlled to comply with an ISO-7 level (following ISO 14.644). Additionally, ISO-5 local areas can also be activated for specific applications via filtered laminar walls. The dimensions of the clean room are 27m L x 17,5m W x 10.5m H and cranes of 10T and 5T are made available.

This vacuum chamber is equipped with built-in optical benches providing high mechanical isolation compatible with interferometric measurements. These benches lay on a heavy seismic concrete block, passively controlled. The thermal-vacuum chambers allow programmable temperature cycles in the range from -196°C to +120°C (LN2/GN2 mode). 5 thermal N2 channels are available on FOCAL 2.

Space Environmental Testing activities are performed according to ECSS standards and the clean rooms are controlled and monitored according to ECSS.Q.70.ST.01.C. The temperature and RH are permanently maintained respectively within 22°C+/- 3°C and 55%+/-10%.

Installation 2: Shaker 200 kN – For vibration testing, CSL proposes in this project a high capacity shaker operating in clean environment (from ISO7 to ISO5). It allows simulation of launch induced vibration, dynamical signature, interface force measurement and fatigue test. Its characteristics are listed hereafter:

- 3 axes

- 48 acquisition channels

- M+P control system with automatic notching

- Sine, random an shock inputs

- Slip table: 1500 x 1500 mm2

- Head expander: 1500 mm diameter

- Max sine force: 200 kN

- Max random force: 160 kN RMS

- Bandwith : 5 – 2000 Hz

For this project, CSL plans to provide to external teams technical support and access to facilities for the qualification of space hardware, in particular thermal vacuum and vibration tests.

Apart the travel and subsistence cost coverage as described in the general section, each approved qualification run at CSL facilities, will include:

- coverage of thermal vacuum facilities running cost, including man power cost for 24/24h monitoring, clean room access, turbomolecular pumping, thermal group with regulated LN2 line, access to control room and contamination monitoring;

- coverage of 200 kN shaker running cost, including clean room and control room access.