AHEAD 2015-2019

Web pages: XACT@OAPA/INAF, IAPS/INAF

Description of the infrastructure

The INAF Distributed Calibration and Test Facility (IDCTF) provides a wide range of services, from testing and calibration of X-ray optics instrumentation using X-ray beams, to equipments for space environment testing. The infrastructure is composed by four facility installations, one located in Palermo (XACT) and three located in Rome (TVLAB, IPC, MEX).

The XACT facility has been designed to be versatile and easy to use both in the testing and calibration of instrumentation at the sub-system level (filters, detectors, optics) as well as in the calibration of fully integrated short focal length X-ray mirrors/telescopes. At the IAPS research centre in Rome Tor Vergata, a number of test equipments is available to support the development of hardware for space missions, mainly in the area of planetology (instruments on board Mars Express, Venus Express, ROSETTA, Cassini) and high energy astrophysics (INTEGRAL, AGILE). These equipments include a thermal-vacuum chamber, a plasma chamber, a device for spectroscopic measurements, plus several clean rooms and other related laboratory facilities.

Installation 1: XACT (X-ray Astronomy Calibration and Testing)

Installation 2: TVLAB (Thermal Vacuum Chamber)

Installation 3: IPC (IAPS Plasma Chamber)

Installation 4: MEX (class 10,000 clean room)

Installation 1: XACT (X-ray Astronomy Calibration and Testing)

A document providing more detailed description of XACT is available here.

The XACT facility of the INAF – Osservatorio Astronomico di Palermo ”G.S. Vaiana” (OAPA) was established in the early 1990s to participate in the development and calibration of the UV/Ion shields of the High Resolution Camera (HRC) of the, still operational, Chandra X-ray Observatory. Since then the facility has been actively used in several research projects including long-term monitoring of EPIC filters, calibration of NASA SOLAR-B X-ray mirror, of Chinese CHANG-E X-ray detector, of Polish SPHINX solar spectrograph as well as supporting laboratory programmes in novel X-ray optics and detectors. The non-staff as well as specific costs of those activities are funded by project grants and contracts to INAF/OAPA, while staff efforts and general costs are covered by INAF. Associated travel costs of visitors have been covered by the respective host institutes. The facility is operative for 220 working days per year, mostly for internal use. No formal record of accesses is available since it was not required by internal regulations. A recording scheme will be activated for dealing with proposed TA.

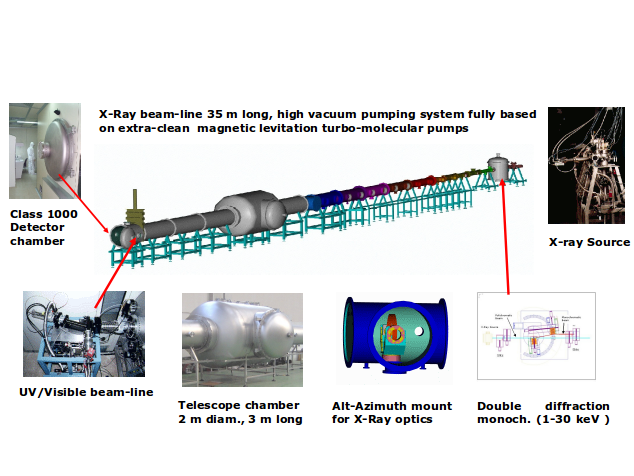

The main components of the XACT facility include: 1) A 35-meter long vacuum beam-line including an X-ray source small chamber, a monochromator chamber 0.8-meter diameter and 1-meter height, a big chamber 3.5-meter long and 2-meter diameter to accommodate large size experiments, and a detector test chamber 1-meter long and 1-meter diameter opening inside a class 1000 clean-room. The diameter of the tubes increases from the source end (150 mm) to the telescope chamber to allow a full area illumination of 800 mm diameter, minimizing the volume and the internal surface of the pipe. The vacuum pumping system is entirely based on magnetic levitation turbo-molecular pumps, and on oil-free rotary pre-vacuum and back-up pumps. A minimum pressure of 5 x 10−8 mbar can be achieved, while normal operation is in the 10−7 mbar scale; 2) Three electron impact micro-focus X-ray sources, providing characteristic lines and bremsstrahlung continuum soft X-ray photons in the energy range 0.1-20 keV. The sources are very efficient, and depending on the anode material and operating parameters, they can produce X-ray fluxes in full illumination ranging between 100 and 50000 photons s−1 cm−2 at about 34 meters distance from the source; 3) X-ray detectors (proportional counters, MCP detectors, and solid state detectors) and monochromators (transmission grating, fixed exit double Bragg diffraction) covering the energy range 0.1-30 keV; 4) A large number of vacuum compatible micro-positioning systems including an alt-azimuth mount for testing grazing incidence X-ray optics. 5) A vacuum UV beam-line attached on a side port of the detector test chamber of the main beam-line, equipped with sources, monochromator and detectors operating in the wavelength range 10-3000 A.

A suite of software applications, with user-friendly interfaces, based on the NI Labview™ software platform allows the XACT full remote control of the operations. A well-equipped mechanical shop including a CNC lathe and milling machines, and support facilities such as a class 1000 clean room, class 100 clean benches, chemical hub, optical microscope, etc. are also available and will be part of the XACT/OAPA participation to the TA offer.

Installation 2: TVLAB (Thermal Vacuum Chamber)

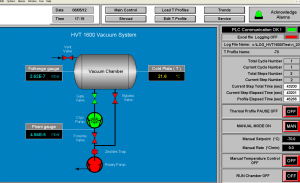

The TVlab is a thermal-vacuum chamber used for qualification tests. Established since 1992 in the framework of the MARS96 project, it remained non-operative for several years due to difficulties following relocation. Afterwards, an appropriate location was found within the space assigned to the IAPS laboratories and the full equipment regenerated with the help of ASI funding assigned to different projects. The TVLAB is now placed inside a 100,000 class clean room and fully operative. The chamber features a volume of 1600 litres and a limit vacuum of 10-7 mbar (the primary vacuum is 10-2 mbar). The temperature range control is between -70 and +100 oC. The cycles can be handled in both automated or manual modalities. A data acquisition system (National Instruments cRIO9074 plus nominal and redundant workstations) allows for data recording and monitoring of 32 temperatures.

Installation 3: IPC (IAPS Plasma Chamber)

The plasma chamber developed at INAF/IAPS is an experimental apparatus capable to reproduce a large volume ionospheric environment, which is particularly suitable to perform studies on a variety of plasma physics subjects that can be summarizes as follows:

-

functional tests of experiments envisaged to operate in a ionospheric environment (sensors exposed to space plasma);

-

characterization and compatibility tests of components for space applications (materials, satellite paints, photo-voltaic cells, etc.);

-

calibration of plasma diagnostic sensors;

-

basic plasma physics experiments (interaction of charged bodies with plasma, two plasma interaction processes, propulsion and power generation in space through electrodynamic tethers);

-

tests on active experiments which use cathodes and/or plasma sources (ion thruster, ion beam neutralizers, hollow cathodes, field effect emitters, plasma contactors).

Installation 4: MEX (class 10,000 clean room)

A clean room is available at IAPS to carry out measurements and/or characterisations on sensors and instruments, at system or equipment level, and to assembly experiments in different domains. The clean room is a L-shaped environment characterised by a 10.000 class (FS 209E), or ISO 7 (ISO14644-1), arranged over a total surface of about 20 m2. A laminar flow blanket is available inside allowing to reach a 100 class (or ISO 5) and dryers are available as well. The room has a temperature (21°C ± 3°C, adjustable) and humidity (50 % ± 10 %, adjustable) control system, optical benches in granite and steel, steel working tables and chairs. The clean room was used for the assembly of the optics and electronic equipments of PFS experiment (Planetary Fourier Spectrometer) on-board Mars Express and Venus Express missions. The calibration of ISA (Italian Spring Accelerometer) triaxial accelerometer, in the frame of ESA BepiColombo cornerstone mission to be launched to Mercury in 2018, has been recently carried out in the clean room.